How Chrysler electronic ignitions work, and what to check if they don't

Share

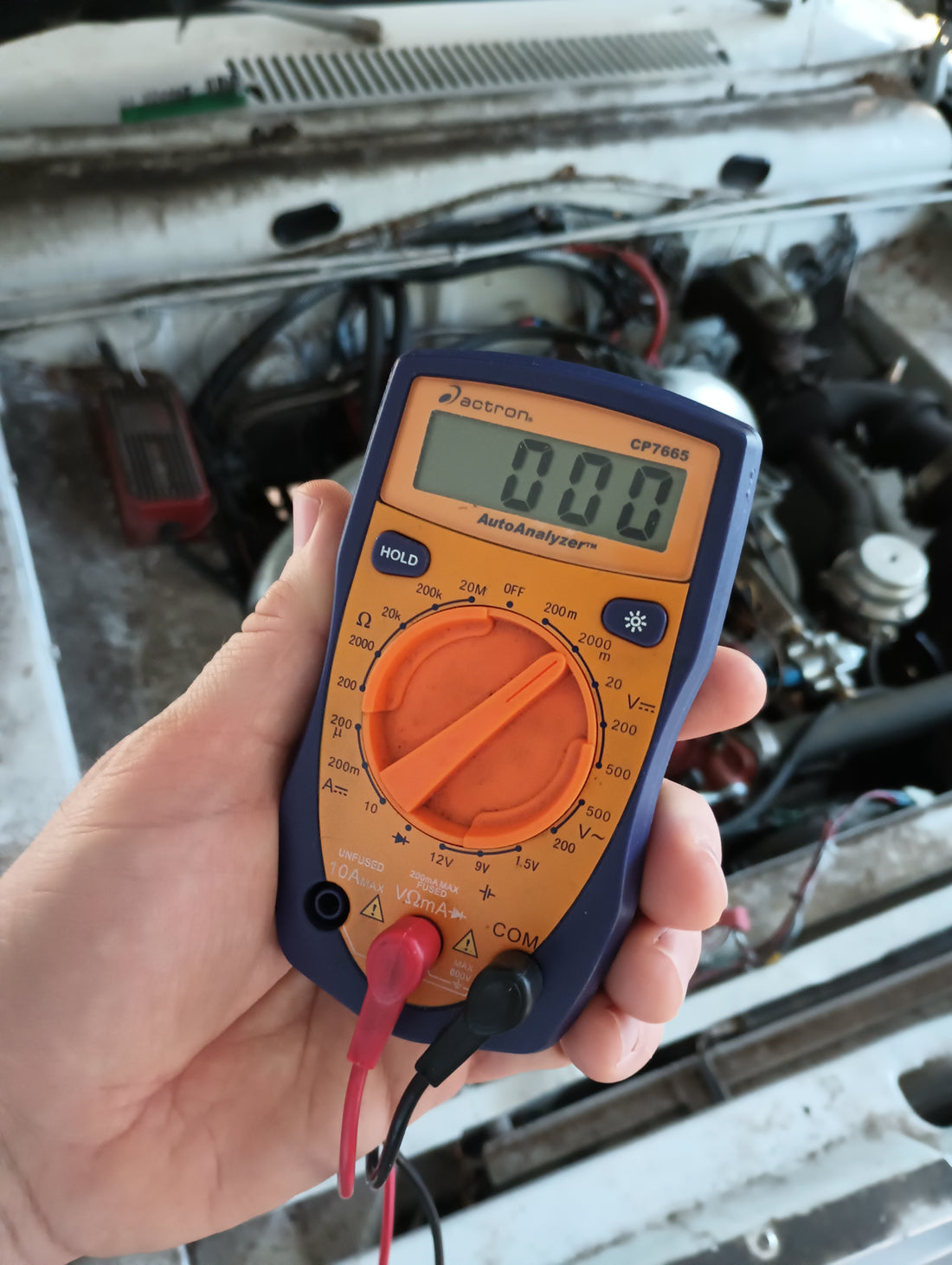

Are you having trouble with a Mopar electronic ignition not sparking? This article covers how the ignition should work, and how to test if everything is working. In addition to standard tools, you'll need a multimeter to run these checks, and you'll need to know how to use it.

Ignitions covered here

This covers the factory ignition system that Chrysler started rolling out in 1972. It does not cover later ignition systems - Lean Burn, the K-car distributors, the Magnum V8s, or distributorless ignitions. It also does not cover aftermarket ignitions if they don't work like stock. Some performance ignitions like the ones sold by FBO may look like they're factory ignitions, but internally work a bit differently.

How the ignition works

When Chrysler rolled out their ignition system, electronics weren't cheap. A single transistor could cost a couple dollars, and that's not adjusted for inflation. The idea of sticking a microprocessor in an ignition module would have been science fiction. What Chrysler built instead was a simple transistorized replacement for breaker points. These didn't exactly copy what the points did, but the results were accurate, affordable, and reliable. At least they're reliable if you have a source of quality parts. Here are the components of Chrysler's ignition system that we will focus on.

- The ignition module, or Electronic Control Unit.

- The coil.

- The ballast resistor.

- The pick-up in the distributor.

The pick-up coil is what sets the process in motion. The distributor has a centrifugal and vacuum advance, just like a points distributor, which determines timing mechanically. The distributor has a reluctor wheel with one point for every cylinder, a magnet, and a coil of wire. It's similar to an AC generator, except designed to create short pulses instead of continuous current. When a tooth on the reluctor wheel passes in front of the coil, the coil generates a pulse that will trigger a spark from the ignition module.

The ignition module connects to the negative terminal of the coil and acts similar to a set of points: It's an electronic switch. Unlike points, however, the ignition module will ground the coil negative terminal until it receives a pulse from the distributor pick-up coil. When the pulse arrives, it triggers a timer circuit that turns the switch off (like opening distributor points) for a short period of time. When the switch turns off, the coil sparks. Then the ignition module turns the switch back on until it receives another pulse. The ignition module connects to ground through its sheet metal.

At this point, you may be wondering: If the ignition module is switched on all the time, what's stopping it from drawing too much current and overheating? This is where the ballast resistor comes in. This is a simple current regulator. It is a type of resistor whose resistance goes up as it gets hotter. So when more current flows through the resistor, the resistor gets hotter, increases its resistance, and this brings the current back down. The ballast resistor both limits current and reduces the voltage at the coil. While cranking, the system bypasses the ballast resistor to deliver a hotter spark. The ignition switch does this through two separate terminals: IGN1 supplies 12 volts in Run that are routed through the ballast resistor, while IGN2 supplies 12 volts in Start to bypass the ballast resistor. Only one of the two IGN terminals is hot at a time.

First test: Do you have power to the coil?

So, you don't have spark, and you've checked at the coil wire itself to make sure this isn't a case of the spark getting out of the coil but not making it through the distributor. Here's what to do when that happens.

The first thing to check if you don't have spark is to make sure your coil is getting power - both with the key in Run and in Start. (Remember that the power goes through a different circuit while starting, so one may be good and the other bad!) Set your multimeter to volts and check the voltage from the coil positive wire to ground. You should see battery voltage in Start (or close to it; if the starter is still connected, it will pull the voltage down), and significantly lower with the key in Run. Six volts is fairly common; that's the ballast resistor doing its job.

If you don't have almost full battery voltage to the coil in Start, something's wrong with the ignition switch or the wiring.

If you don't have power in Run but do have power at Start, check the voltage to ground on both sides of the ballast resistor, with the key in Run. If you have battery volts coming to the ballast resistor, but no voltage on the other side, you've got a bad ballast resistor. If you do have volts on both sides, something is wrong with the wiring.

Checking the other side of the coil

If the power to the coil checks out, measure the voltage from the negative terminal of the coil to ground with the key in Run. You should have a low voltage, anywhere from 0 to 1.5 volts.

If you're seeing something more like battery voltage, the ignition module isn't working as expected. The module should be grounding the coil, and it isn't. Either there is a break in the wiring, the ignition module isn't working, or the module is not grounded properly.

If the module is some sort of performance unit such as the FBO, it may not ground the coil full time. Check the documentation for the ignition module; if it says you can eliminate the ballast resistor or that it actively controls the dwell, it probably doesn't stay on full time.

All that checks out - now what?

If the coil has power and the negative terminal is being grounded with the key on, you'll need to check individual parts. You may have a problem with the coil, the ignition module, or the distributor pick-up. Or the wiring; make sure you don't have any damage there, particularly at the connectors.

The coil can be the easiest one to test - just be careful not to zap yourself. Turn the key off and disconnect the negative terminal. Then turn the key on and briefly short the negative terminal to ground using alligator clips or something similar. If you get a spark, you've got a good coil; if not, you need a new coil.

With the distributor pick up, you can set the multimeter to ohms, unplug the pick up, and measure across its two terminals in the wiring. A room temperature pick up coil should measure 250 to 800 ohms. If you're really not sure if it works, you can pull the distributor out, set the multimeter to AC voltage, and spin the distributor in a drill. You should measure a few volts across the two wires coming from the pick up.

It's also possible to do a quick test of test the ignition module, although this may not work with some module brands. Unplug the pick up coil and leave everything connected. Turn the key to Run and tap the exposed terminal of the ignition module side of the distributor pick-up connector to ground. Most modules will trigger a spark when this is tapped to ground. If you get a spark with this test, but not while cranking, it's likely an issue with the pick-up or its wiring.

If the distributor pick up and the coil both check out, and the wiring is OK, the ignition module is probably at fault.